"The business policy of the Fiers Mechanika Ltd. is: to play a high-ranking role on the national and foreign markets with the manufacturing of precision parts, individual tools and devices, as well as tools and all their clients by a continuous quality assurance to supply perfect goods. At the Fiers Mechanika Ltd. each leader has the quality assurance task and responsibility to authenticate their obligation in relation to the quality exemplarily. The Fiers Mechanika Ltd. assures that all workers get to know with - including the newly joined colleagues - the quality politics of the company, as well as the fundamental goals, the structure, the methods for the realization of the quality system, and also expectations placed against them..."

ISO Quality Insurance system

Our quality system corresponds since 1998 the international standards of the MSZ EN ISO 9001 which was certified by the Swiss company Digant Ltd

Alliance for Excellence

Alliance for Excellence We are proud that beside the sucessful customer audits our work has received other type of recognition too: Fiers Mechanika Ltd. took part in 2011 in the Grundfos Supplier’s Excellence Program, which was organised by one of our biggest customer Grundfos Magyarország Gyártó Ltd. and was brought to life with the help of the Non-Profit Association of Excellence. After the self assessment, which was based on the EFQM business model our company performed 3 projects. From these 3 projects one project was linked to the Grundfos Magyarország Gyártó Ltd. Thanks to the successful completition of the program, our company has earned the Committed to Excellence (C2E) recognition. Fiers Mechanika Ltd. took part also in the Grundfos Supplier’s Excellence Program’s SEP2 phase in 2012 and 2013. At the beginning of 2013 our company has created self assessment, which was based on the EFQM business model and their 9 sub-criteria. In February 2013 there was site visit, after this visit the 3 new projects has been choosen and as the closure of the program a new self assessment and a site visit has been done at the beginning of 2014. http://www.kivalosag.com/

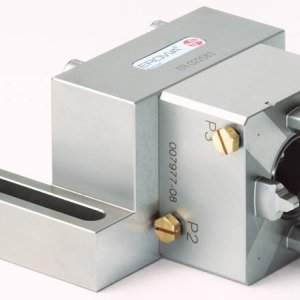

EROWA system

Our company started to use the EROWA clamping system in 1994. System reliability, accuracy, efficiency lived up to expectations and has since been fully implemented, it has been applied to all processing device and measuring device. More details about the EROWA system can be found on the below website: http://www.erowa.com

Quality Control lab equipments

In our control labs 3 technician colleagues our checking the products before shipping. For this checking 3D measuring machines and optical equipment, surface roughness testing equipment are available. The measuring range is on our biggest machine is 1000x2200 mm.