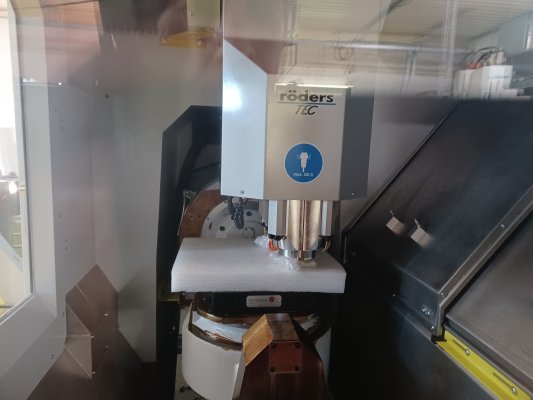

THE RÖDERS PRECISION MACHINE HAS ARRIVED

The high-precision Röders equipment has arrived at our tool manufacturing plant.

The RXP601DSH Z2 simultaneous five-axis machine has a number of options. One of the most significant of the options ordered is that the machine is equipped with two spindles. In addition to the 42,000 (1 / min) speed milling spindle, we purchased the 80,000 (1 / min) speed spindle for extreme small diameter grinding tools.

Two separate closed-circuit cooling circuits ensure that the machine's main units are continuously tempered during machining.

Selecting the right tool and setting the operating temperature is still a prerequisite, but micron-precision machining can be performed. Two measuring probes are used to control precision machining, which, together with the measuring software built into the controller, is suitable not only for measuring but also for creating complex reports.

By the end of January, the first-round trainings had already been completed. Our first experience is great, we are confident that we will find the orders with which we can take advantage of the uniqueness of the machine.