In June, another CNC lathe was put into operation in our II. factory. The machine tool from Japan also has a counter-spindle, a driven tool and a Y-axis. The machine is suitable for the production of highly complex precision workpieces. Individual and with the optional fiber feeder, larger parts can be machined.

In May, our grinding machine fleet has been expanded too, this time we purchased an impeccably renovated SZIM universal mantle grinder, which we hope will serve us for many years. We also replaced our universal milling machine. We have purchased the new TOS FNGJ40 milling machine with a range of 600 mm with several options, the most important of which for us is that it is equipped with a heidenhain measuring rod on each axis, which will ensure high accuracy in production.

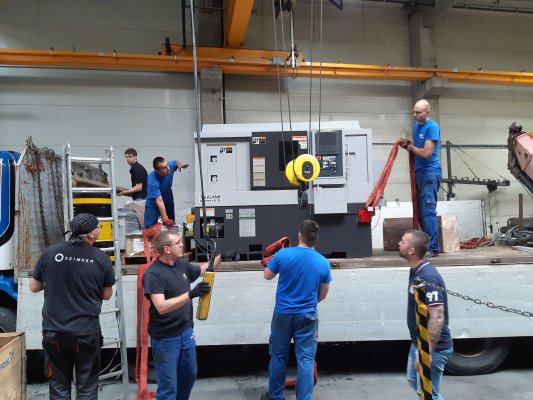

This year, we are determined to renovate the floor in the CNC hall in our I. factory. In order not to have to stop production for a long time, only our two-week shutdown in the summer was suitable for this work. The renovation involved a number of machine movements, but seeing the new flooring and fresh painted walls was well worth the effort.